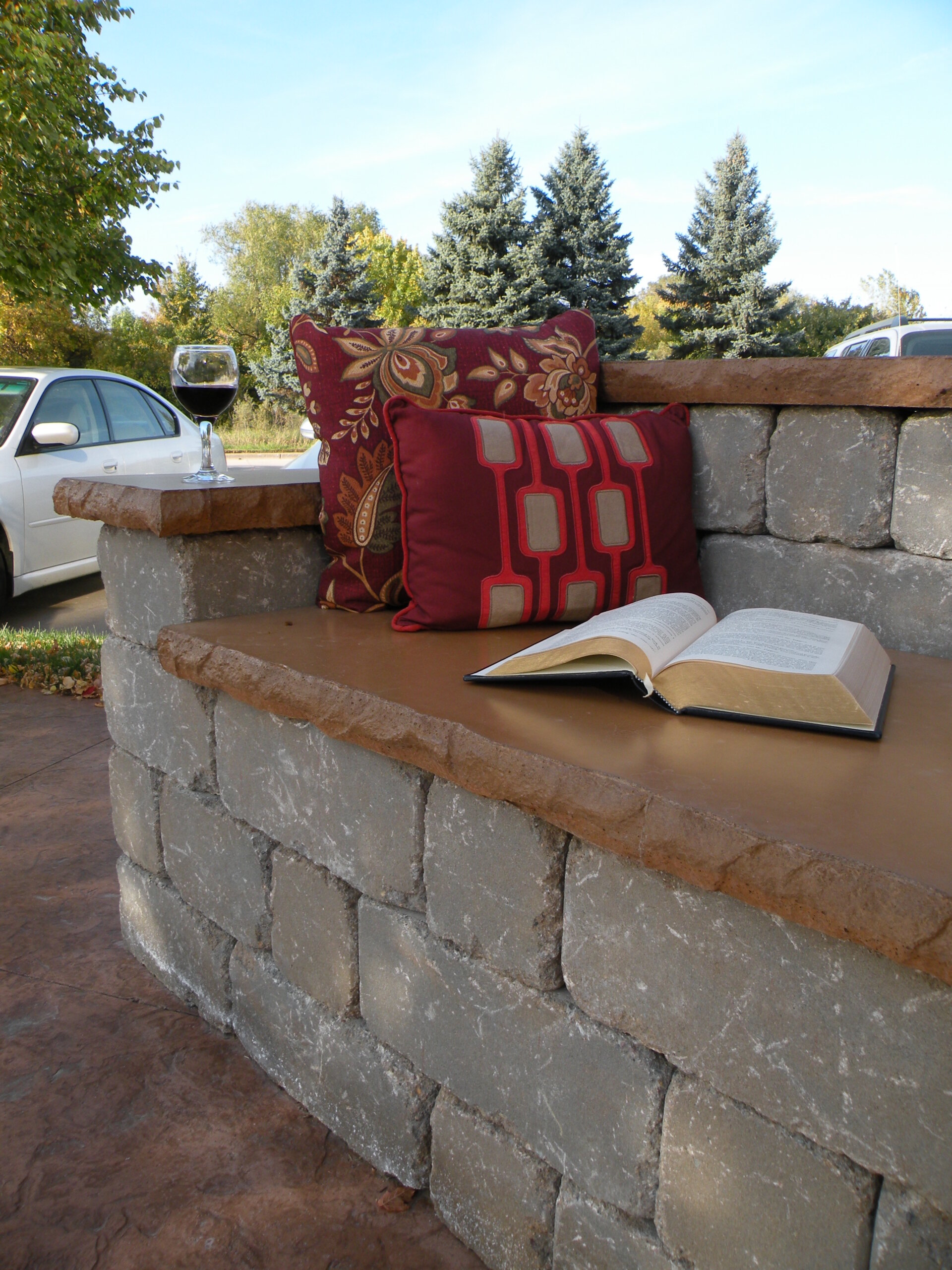

TechMix® Premium Concrete Countertop Mix is a fast-setting, high-strength mix specially formulated to create countertops, outdoor kitchen tops, bar or table tops, workbench or utility tops.

Use For:

- Precast countertops

- Outdoor kitchen tops

- Bar or table top

- Workbench or utility top

- Precast wall caps

- Precast mantels

- Precast lintels

| Color | BOM | UNIT SIZE | UNIT WEIGHT | PACK QUANTITY | PACK WEIGHT | PACK TYPE |

|---|---|---|---|---|---|---|

| Gray | 103434 | 50 lb. bag | 50 lb. | 64 | 3200 lb. | Pallet |

| White | 104082 | 50 lb. bag | 50 lb. | 64 | 3200 lb. | Pallet |