TechMix Premium Concrete Countertop Mix Commonly Asked Questions

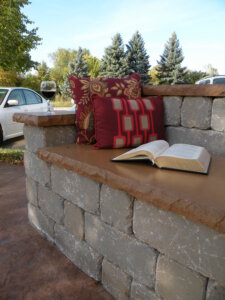

Looking for a product to use during the colder months without going outside? TechMix® Premium Concrete Countertop Mix is a fast-setting, high-strength mix specially formulated to create countertops, bar or tabletops, workbenchs, or utility tops. Use this product for any interior products you may have.

Some commonly asked questions:

When using more than 1 bag, do I need to mix every bag before pouring it into the form?

- No, it is not required to mix all the bags. Spread the first bag to cover the entire surface of the mold, then pour the subsequent bags on top of the first bag. We recommend using rubber gloves to gently mix or knead the top when all the material has been poured into the mold. Do not use a paint stick. It could scratch the melamine surface and leave a scar to form on the surface of the countertop. If you are adding pigment, mix that with the dry powder before adding water.

Do I have to mix for 3 minutes, let the material set for 2 minutes, and then remix for 2 minutes?

- Yes, mix time is very critical. Not following these steps can create inconsistencies in the mix. How do you vibrate the form using a rubber mallet? Tapping around the perimeter of the mold works well to remove any air bubbles. We recommend 7-8 tapping sessions every 6”.

If I leave the countertop in the forms longer, will it be less fragile?

- The countertop is not fragile, but it can be scratched. Be careful when removing the forms not to pry against the countertop. This could cause scratches, chips, etc.

How durable are concrete countertops?

- Once cured, concrete is highly durable, but like any other material, the edges and corners are the most susceptible to damage or chipping. Standard precautions should be taken when working with pots, pans, or other items.

Do concrete countertops stain?

- Concrete in its natural state is porous and will stain. Concrete countertops are sealed for stain and water resistance. However, spills, especially acidic or oily liquids, should be cleaned immediately. Mild soap and water are the best ways to clean the surface.

How do I clean and disinfect my concrete countertops?

- The best cleaners are mild soap and water. Never use harsh chemicals or abrasive cleaners. Bleach can discolor the surface, and abrasive cleaners can scratch the sealer.

Can I cut directly on concrete countertops?

- It is usually recommended that a cutting board or protective surface be used. Knife marks can scratch the sealer, so use a cutting board when chopping or preparing food. Cutting on the concrete countertop won’t hurt the concrete but will damage the sealer, which can affect the sealer’s ability to keep out water and stains.

Can I set hot pots and pans on concrete countertops?

- Hot pots or pans can damage the sealer on countertops, so potholders or hot pads should always be used. Placing hot pans on the concrete countertops should be avoided. Concrete is very heat resistant, but the issue is damaging and/or discoloring the sealer.

What kind of maintenance do concrete countertops require?

- It does not take much to maintain a beautiful surface. A food-grade beeswax should be applied about once a month to help protect the sealer. Buff it on and buff it off.

What should I use…penetrating or surface sealers?

- One essential consideration when choosing between penetrating and surface sealers is that sealing polished concrete can be challenging. The surface may be too smooth for many surface sealers to stick to. When concrete is polished, a penetrating sealer or wax might be best. Here are a few essential tips, but understand that many concrete sealers are readily available and may serve your purpose.

- Penetrating Sealers are applied to concrete and, once dried, can be nearly invisible. They often don’t affect the appearance of dry concrete. Some products dry the concrete, while others provide a darker, wet look.

- Surface Sealers are the most common sealers on the market. A wide range of types with widely differing chemistries and varying appearance, performance, and longevity degrees. A few of the most common surface sealers are wax and acrylics.

- The most basic sealer is wax. Wax is both a penetrating and film-building sealer, depending on how much is used and how it is applied. Generally, a high-quality floor wax that contains carnauba and beeswax, or just pure beeswax, is used. Automotive paste wax should not be used because of the additives it contains.

- Wax produces a finish that brings out the character of the concrete’s color and visual texture. Wax is an easy-to-apply sealer but may darken bare concrete. Wax cannot be scratched, although the concrete can get scratched or gouged. Wax will act as a “wear surface” and is easy to reapply and must be applied frequently to remain effective.

- Many sources report that almost anything can stain waxed concrete if left on the surface for an extended time, and exposure times must be short to avoid any surface staining. Hot temperatures and acids like vinegar or lemon juice tend to strip off the wax.

- Acrylics (solvent based or water-based) are common concrete sealers. They were developed for sealing floors and driveways and offer modest protection. Solvent-based acrylics can darken the concrete, while most water-based acrylics tend to look pale like it does when it is dry. Acrylics are thin-bodied liquids that are brushed, sprayed, or rolled onto the concrete. Acrylic sealers sit on the surface of dense, impermeable concrete used in most concrete countertops. Acrylics generally provide modest heat resistance but are UV resistant. Acrylics offer good stain protection but are easily scratched. Scratches often leave the concrete completely bare and unprotected. Acrylic sealers often require frequent reapplication because they tend to scratch and wear off, especially if the surface they were applied to was not adequately prepared.

What is the difference between a precast and pour-in-place countertop?

- There are two methods for creating concrete countertops. The “precast” concrete countertops are preferred because they allow more customization, control, and level-smooth surfaces. “Pour-in-place” countertops are generally less refined and do not allow for some custom design elements but may be a good alternative for specific projects. Though the precast method may seem more complex, the skills required for final surface finishing are initially less demanding (for most Do-it-Yourselfers) than the pour-in-place method.

If you are looking for more information about the TechMix Premium Concrete Countertop Mix visit the product’s page on our website or contact us!