Importance of Low-Dust Additive

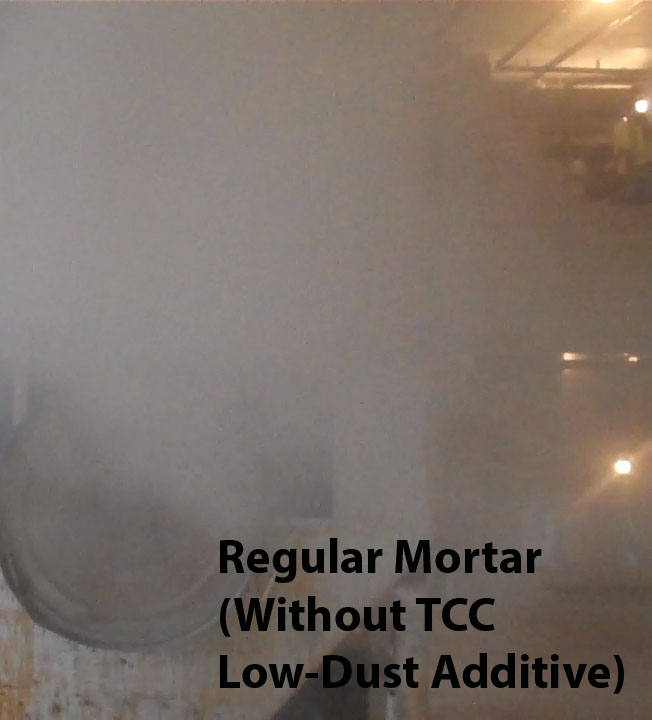

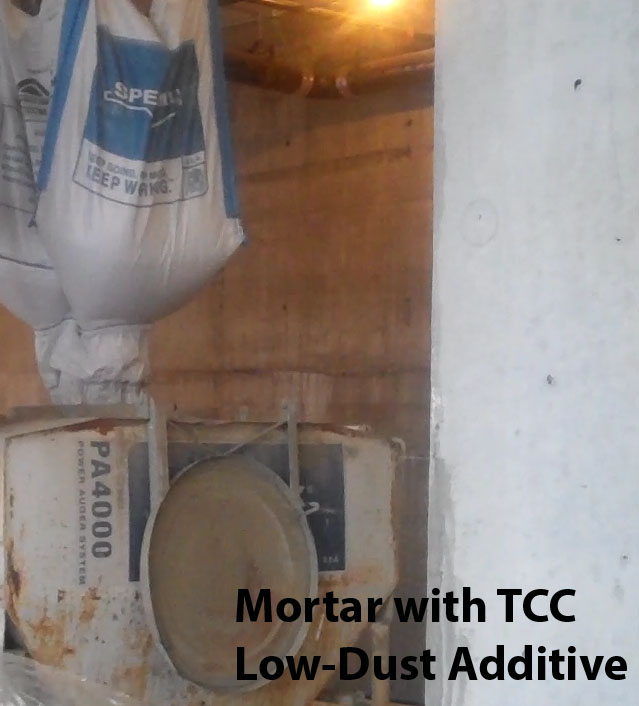

Using a Low-Dust Additive with mortar or grout is important because the dust created when working with sand and cement blended powders can be harmful to the health of anyone breathing this dust. The longer the exposure, the greater the possibility of health issues such as silicosis. Preventative steps can be taken by using the TCC Low-Dust Additive to significantly reduce the amount of dust created when pouring, blending, or mixing dry powders. Confined spaces are safer with less dust and increased visibility, job sites stay cleaner, and nearby parked vehicles aren’t exposed as much cementitious residue. Dust control is especially useful in residential projects, projects with high foot traffic, and other areas where humans, pets, structures, electronics and machinery can be negatively affected by dust accumulation. Because of these hazards, OSHA has regulations that limit exposure to crystalline silica and are proposing major updates to those rules for all industries.

Workers who inhale very small crystalline silica particles are at increased risk of developing serious silica-related diseases. These tiny particles (known as “respirable” particles) can penetrate deep into worker’s lungs and cause silicosis, an incurable and sometimes fatal lung disease. Exposure to crystalline silica also puts workers at risk for developing kidney disease, lung cancer, and other potentially debilitating respiratory diseases such as chronic obstructive pulmonary disease (COPD).

Some Frequently Asked Questions:

- What is silicosis?

- Silicosis is an incurable, sometimes fatal lung disease caused by breathing in very small particles of silica dust. This causes tissue to inflame and scar which can affect your ability to breathe. There are three types of silicosis. Acute silicosis develops just weeks or month after exposure to very high levels of crystalline silica and is the most fatal. Accelerated silicosis develops five to ten years after exposure to moderately high levels of crystalline silica. Chronic silicosis is the most common type of silicosis which develops 10+ years after exposure to low levels of crystalline silica. To learn more about silicosis, visit the American Lung Association’s website on silicosis, or view the YouTube video Silicosis: A Preventable Disease.

- How long has silicosis been an issue?

- The U.S. Department of Labor has been making efforts to heighten awareness of silicosis since the early 1900s. Click here to view a 1938 video published by the Department of Labor and featuring former Secretary of Labor, Frances Perkins describing the hazards of working with silica dust.

- How does TCC Low-Dust Additive work?

- The fine cementitious and silica particles attach to the Low-Dust Additive, staying suspended in the dry concrete and mortar mix powder until it is mixed with liquid.

- What products can I add Low-Dust Additive to?

- Low-Dust Additives available to be added to most of our commercial products including mortar and corefill grout products. Contact your sales representative for more information.

- Does the addition of Low-Dust Additive change the product?

- No. Low-Dust Additive can reduce dust by over 80% without compromising the strength, properties, or workability of the specific mix.

- When is Low-Dust Additive added to the specified mix?

- The Low-Dust is added to the specified mix at our plants during the manufacturing process for consistency and convenience.

- Does Low-Dust Additive really work?

- Yes! Low-Dust Additive can reduce dust by over 80%. Click here to watch it in action on a commercial project in Minneapolis, Minnesota.

For more information on the Low-Dust Additive, check out our FAQ, or this video to see Low-Dust in action!